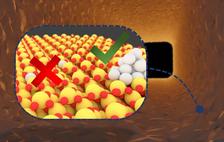

Schematic representation of a noble metal catalyst with inactive single atoms (left) and active clusters (right; noble metal: white; carrier metal: yellow; oxygen: red). (Credit: KIT, Florian Maurer [Source])

Certain catalysts work more effectively with small clusters of noble metal atoms. This is the result of a study at PETRA III by a team from the Karlsruhe Institute of Technology (KIT), for which X-ray measurements. The team reports the results in the journal Nature Catalysis.

Billions of noble metal catalysts are used worldwide for the production of chemicals, energy generation, or to reduce pollutant emissions in combustion processes. However, the resources required for this purpose are expensive and their availability is limited. To optimize the use of resources, catalysts based on single metal atoms have been developed. The KIT team could now show that noble metal atoms in catalysts can assemble to form clusters under certain conditions. These clusters are more reactive than the single atoms and, hence, can remove exhaust gases much better.

Many catalysts use nanoparticles of the active component, such as a noble metal, which consist of several thousands of metal atoms. “But only atoms on the outside are active in the reaction, while most atoms remain unused,” explains KIT scientist Jan-Dierk Grunwaldt. By changing operation conditions, the structure of such a catalyst and, hence, its activity may be changed. “At high temperatures in the exhaust gas system of a car, which are reached during a longer drive on a motorway, for instance, interaction between the noble metal and carrier may lead to the formation of single atoms, that are isolated, separate metal atoms on the carrier,” Grunwaldt says.

Such single-atom catalysts might be expected to reach a very high utilization rate of the noble metal components, because all atoms can theoretically participate in the reaction. Contrary to this expectation, however, the team of Grunwaldt, in cooperation with KIT colleagues Christof Wöll and Felix Studt, has found that these atoms first have to form noble metal clusters under reaction conditions to become active. Clusters are collections of a few atoms in the transition region between individual particles and a physical body.

For their study, the researchers specifically induced the formation of single atoms and examined their structure thoroughly during the reaction. With the help of highly specialized X-ray spectroscopy at the measuring station P65 of DESY's X-ray source PETRA III, individual platin atoms could be localised on the cerium oxide (CeO2) substrate. “Under reaction conditions, the individual platinum atoms incorporated into the catalyst surface form small, catalytically active clusters,” explains DESY researcher Edmund Welter, head of the measuring station. “Under certain conditions, the platinum atoms from these clusters are re-integrated into the surface, from where the cycle can start again. X-ray absorption spectroscopy fine-structure shows us the exact position of the platinum atoms in the surface of the cerium oxide substrate.”

Thanks to a combination of measurements and theoretical calculations, which were used for the first time ever for this class of catalysts, the team succeeded in explaining why platinum atoms frequently have a low activity. “To convert pollutants, they usually have to react with oxygen in the catalyst,” says KIT researcher Florian Maurer. “For this, both components must be available at the same time and place, which cannot be achieved for isolated platinum atoms, as the oxygen for the required reaction is much too strongly bound to the carrier component – in our case cerium oxide. After breaking the platinum-cerium oxide bonds, platinum atoms can move across the carrier surface. In a next step, these platinum atoms form small platinum clusters, on which the reaction takes place much faster than on single atoms.”

The team’s studies prove that neither nanoparticles nor isolated atoms reach the highest activity. “The optimum lies in between. It is reached by small noble metal clusters,” Grunwaldt says. “Stabilising these noble metal clusters might be the key to substantially reduce the consumption of noble metals when producing catalysts. For years, increasingly fine distribution of the noble metal component has been one of the main strategies in designing new catalysts. Our experiments have now revealed the limits in the atomic range.” The results of the study will now be used for knowledge-based design and development of catalysts of enhanced stability and long-term activity. This will be a major focus of the work of the Karlsruhe Exhaust Gas Center of KIT, led by co-author Maria Casapu.

(Source: KIT press release / DESY news)

Reference:

Tracking the formation, fate and consequence for catalytic activity of Pt single sites on CeO2; Florian Maurer, Jelena Jelic, Junjun Wang, Andreas Gänzler, Paolo Dolcet, Christof Wöll, Yuemin Wang, Felix Studt, Maria Casapu, Jan-Dierk Grunwaldt; Nature Catalysis, 2020; DOI: 10.1038/s41929-020-00508-7