The use of permanent magnet (PM) material for magnets in modern multi-bend lattices is particularly advantageous for achieving a compact design but also for reducing the power consumption during operation. In the hybrid six-bend achromat lattice (H6BA) for the proposed PETRA IV storage ring, all bending magnets will be made of permanent magnets, following the successful implementation of permanent magnet dipoles with longitudinal gradient at the ESRF for the previous EBS upgrade. The design concept for the dipoles is a further advancement of the ESRF-EBS dipoles with longitudinal gradient. For the PETRA IV lattice, three different types of permanent dipole magnets will be used which include a combined function dipole-quadrupole magnet with both longitudinal and transverse gradient (DLQs). As for all high brilliance light source magnets, there are very demanding field quality requirements for these dipoles.

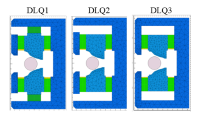

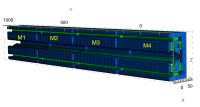

Three different types of permanent magnet dipoles will be used in the H6BA cell. Out of three dipole magnets, one has both transverse and longitudinal gradients which is DLQ1. It consists of four modules (M4-M1) with a ~23% stepwise decreasing magnetic field; the field-to-gradient ratio B/G remains, however, constant. The other two magnets, DLQ2 and DLQ3, have only a transverse gradient. DLQ2 has four modules with identical magnetic field amplitude and gradient, and DLQ3 has six modules with identical magnetic field and gradient. Figure 1 shows the cross-section of the DLQs in the magnetic model. The overall design with a C-shaped yoke provides a less constrained design of the photon extraction chamber and an easier installation process of both, DLQs and vacuum chambers. Due to the moderate gradient values in the DLQs (B/G~25.8mm), a modified dipole design with slanted poles is applied resulting in an efficient design with a compact cross-section of about 120×200 mm2 (w × h). The yoke and poles are made of soft iron. The magnetic material used for the DLQs is SmCo. This PM material has the advantage of higher resistance to radiation damage and lower temperature dependence. The design studies started with DLQ1 shown in Figure 2, which has higher field and gradient compared to the other types and also provides a higher complexity due to the longitudinal gradient. All solutions found for this magnet can subsequently be directly transferred to the other DLQ types.

All the magnetic field properties obtained from 3D Radia simulations are transferred to a mechanical design for all modules and the complete DLQ1 which will lead to manufacture of a first prototype in the near future. The magnetic measurement system for the DLQs will be a stretched wire bench. The compact size and reduction in power consumption and operating costs of PM magnets is a fruitful choice for upcoming future accelerator facilities.

Contact: M.Gehlot, M. Tischer

Publications and further literature:

M. Gehlot, P. N'gotta, T. Ramm, M. Tischer and J. Chavanne,"Design of permanent magnet dipoles-quadrupoles with longitudinal gradient for the PETRA IV storage ring", Proceedings of 14th International Particle Accelerator Conference,https://doi.org/10.18429/JACoW-IPAC2023-WEPM100.

R. Bartolini et al., “Status of PETRA IV Machine Project”, in Proc. IPAC2022, Bangkok, Thailand, doi:10.18429/JACoW-IPAC2022-TUPOMS029.

J. Chavanne et al., “Prospects for the use of permanent magnets in future accelerator facilities”, in Proc. IPAC2014, Dresden, Germany, doi:10.18429/JACoW-IPAC2014-TUZB01.