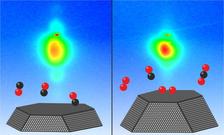

Averaged form of the platinum nanoparticles at the start of the experiments (left, surrounded by carbon monoxide) and after the fusion process (right, during reaction of oxygen and carbon monoxide into carbon dioxide). By recording 2D diffraction patterns (in the background) the change in the form of the particles can be observed in a live view (U. Hejral).

The platinum nanoparticles found in a car’s catalytic converter fuse together during its operation, forfeiting some of their efficiency as a result. Scientists from Hamburg and DESY have now observed this process live on the nano-scale.The examination, which was carried out in a special type of reaction chamber, for the first time provides experimental data on the changes undergone by catalyst nanoparticles under operation conditions, as the scientists Uta Hejral and Andreas Stierle from DESY’s NanoLab report in the journal “Nature Communications”.

Catalysts are materials that speed up chemical reactions or that make them possible in the first place, without themselves being consumed. They are not only found in cars, but are in fact one of the most important tools used by the chemical industry. “Over 90 percent of all high-purity chemicals are made with the help of catalysts, for example”, Hejral explains. Many different metals and alloys are used for this purpose. In cars, a mixture of platinum, rhodium and palladium convert toxic carbon monoxide and harmful oxides of nitrogen into less hazardous compounds.

The efficiency of a certain amount of catalyst material increases with the size of the exposed area. “A sphere with a diameter of one centimetre has a surface area of just over three square centimetres,” Hejral explains. “In principle, you could make 1.3 trillion tiny spheres with a diameter of ten nanometres, from the same quantity of material, and these would have a total surface area of 386 square metres – roughly two tennis courts.” One nanometre is a millionth of a millimetre. However, the size of the particles can change during operation, and this reduces the performance of the catalyst.

The researchers used this sample to convert carbon monoxide (CO) and oxygen (O2) into carbon dioxide (CO2) in a reaction chamber at 280 degrees Celsius. The efficiency of the reaction was measured directly using a mass spectrometer. The scientists were also able to monitor changes in the nanoparticles during the reaction with the help of a narrow X-ray beam. These measurements were conducted at the European Synchrotron Radiation Facility (ESRF) in the French city of Grenoble.

Under reaction conditions, the shape of the nanoparticles changed to different degrees, depending on the ratio of the two metals. “Pure platinum nanoparticles grew appreciably in height, doubling from two to about four nanometres,” reports Hejral. “That came as a real surprise.” Pure rhodium particles, on the other hand remained very stable, hardly changing in height. The particles with an equal mixture of platinum and rhodium were almost as stable.

“The study shows that the platinum nanoparticles use the energy released by the chemical reaction to fuse together,” comments Hejral. “Whereas at the beginning of the experiment, the platinum particles consisted of about 15 000 atoms each, by the end they contained about 23 000. As a result of their agglomeration, the area of the carrier that was coated with platinum nanoparticles dropped from initially 50 percent to about 35 percent.” The researchers believe that the platinum particles strive to adopt a more favourable spherical shape, which is associated with a lower energy level. The manufacturing of nanoparticles with shapes close to the ones adopted after this agglomeration could result in a reduction of the particle rearrangement and hence of the drop in efficiency.

Catalysts for cars are already largely optimised based on experience, but there are still many open questions concerning the atomic scale processes that take place during reaction conditions. They need to be understood to improve the catalyst lifetimes and efficiency. The new method yields insight into this and can be used for applications other than catalytic converters, too, as Andreas Stierle points out, who was in charge of the experiment and who is also the head of the DESY NanoLab. “Our method allows us to determine the optimum mixtures and particle sizes experimentally. This can be used for catalysts in all kinds of different applications, and could open up entirely new possibilities in the chemical industry.”

(from DESY Press News)

Original-Artikel DOI 10.1038/NCOMMS10964