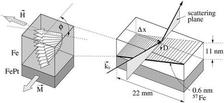

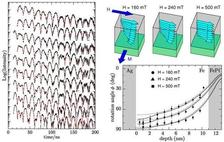

Figure 1: Left: Scheme of the spin structure in an exchange-spring bilayer consisting of a soft-magnetic layer (Fe) on a hard-magnetic layer (FePt) with uniaxial anisotropy. An external field H is applied perpendicular to the remanent magnetization M of the hard layer.

Right: To image the resulting magnetic spiral, a tilted ultrathin probe layer of 57Fe is deposited within the soft layer. The magnetic properties in depth D of the film are probed by adjusting the transverse displacement  x of the sample relative to the scattering plane.

x of the sample relative to the scattering plane.

Depth dependent Spin Structure in Exchange-Spring Magnets

Nanocomposite materials consisting of exchange-coupled soft- and hard-magnetic phases are promising candidates for new permanent magnetic materials with giant magnetic energy products [1]. Thin bilayers consisting of a hard- and a soft-magnetic material are ideal model systems to investigate the fundamental properties of this coupling mechanism.

The magnetization of the soft-magnetic film at the interface is pinned to the hardmagnetic film as a result of the exchange interaction. With increasing distance from the interface, the exchange coupling becomes weaker and the magnetization may rotate under the action of an external field. If, for example, the external field is applied orthogonal to the magnetization direction of the hard layer, the magnetic moments in the soft layer arrange in a spiral structure along the normal, as shown schematically in Fig. 1.

Because of the reversible nature of this rotation, this is called the exchange-spring effect [2].

The sample described here is a bilayer system consisting of 11 nm Fe on 30 nm Fe55Pt45, further denoted as FePt. The layers were deposited by rf magnetron sputtering in an Ar atmosphere of 1.5  10-2 mbar on a superpolished Si wafer. FePt was sputtered from a composite target consisting of a number of Pt chips on a high-purity Fe foil to obtain the desired composition.

10-2 mbar on a superpolished Si wafer. FePt was sputtered from a composite target consisting of a number of Pt chips on a high-purity Fe foil to obtain the desired composition.

After deposition, the layer was annealed for 30 min at 800 K to form the hard-magnetic tetragonal L10 phase with a

coercivity of 0.96 T at room temperature, as controlled by hysteresis measurements via the magneto-optical Kerr effect. The rms surface roughness of the FePt layer was determined by x-ray reflectivity to be less than 0.4 nm, indicating that the grain size did not increase too much upon annealing.

To prepare a tilted probe layer within the Fe film, as shown schematically in Fig. 1, a wedge-shaped film with a slope of 0.5 nm/mm is produced by linear variation of the exposure during sputter deposition of Fe. After growth of a 0.7 nm thick 57Fe probe layer the same wedge was deposited with opposite slope. Different depths D in the sample can thus be probed by adjusting the displacement  x of the sample transversely to the incident beam. Finally, the layer system was coated with 3 nm Ag to minimize oxidation.

x of the sample transversely to the incident beam. Finally, the layer system was coated with 3 nm Ag to minimize oxidation.