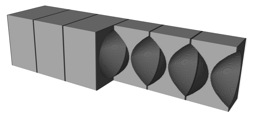

Stack of refractive X-ray lenses.

For a long time it was believed that refractive lenses for hard x rays could not be made. It was believed that the weak refraction of hard x-rays in matter together with the relatively high attenuation would prevent one from making refractive x-ray lenses. However, in 1996, it was shown that refractive lenses could indeed be made (Snigirev, Kohn, Snigireva, Lengeler, Nature 384, 49 (1996)). Since then, refractive x-ray lenses were developed quickly. A large part of this development was done at Aachen University.

The weak refraction (it is about six orders of magnitude weaker for hard x-rays in matter than for visible light in glass) is dealt with by introducing a strong curvature in the individual lens surfaces and by stacking a large number of lenses behind each other.

For hard x rays there is no material that is as transparent as glass is for visible light. Therefore, attenuation is important for all lens materials. In order of optimize the transmission and the aperture of these optics, it is crucial to use lens materials made of elements with low atomic number Z, such as Be, B, C, or Al.

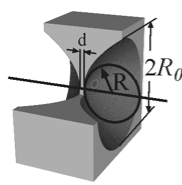

Single refractive X-ray lens.

The weak refraction of hard x rays in matter requires the radius of curvature R of the individual lenses to be small. The spherical approximation holds only for lenses with an aperture 2R0 that is much smaller than the radius of curvature R. Since for most x-ray lens designs the aperture 2R0 is comparable to or larger than the radius of curvature R, the spherical approximation no longer holds. Therefore, for high quality imaging applications, parabolic (aspherical) lenses need to be made.

For imaging applications, such as full-field microscopy, lenses with rotationally parabolic profile (as shown in the pictures above) are ideal. To generate a particularly small focus for scanning microscopy, refractive lenses with small focal length are required, so-called nanofocusing lenses. In cooperation with the Institute of Semiconductors and Microsystems (IHM, TU Dresden) we are developing this special kind of x-ray optics.