Application procedure

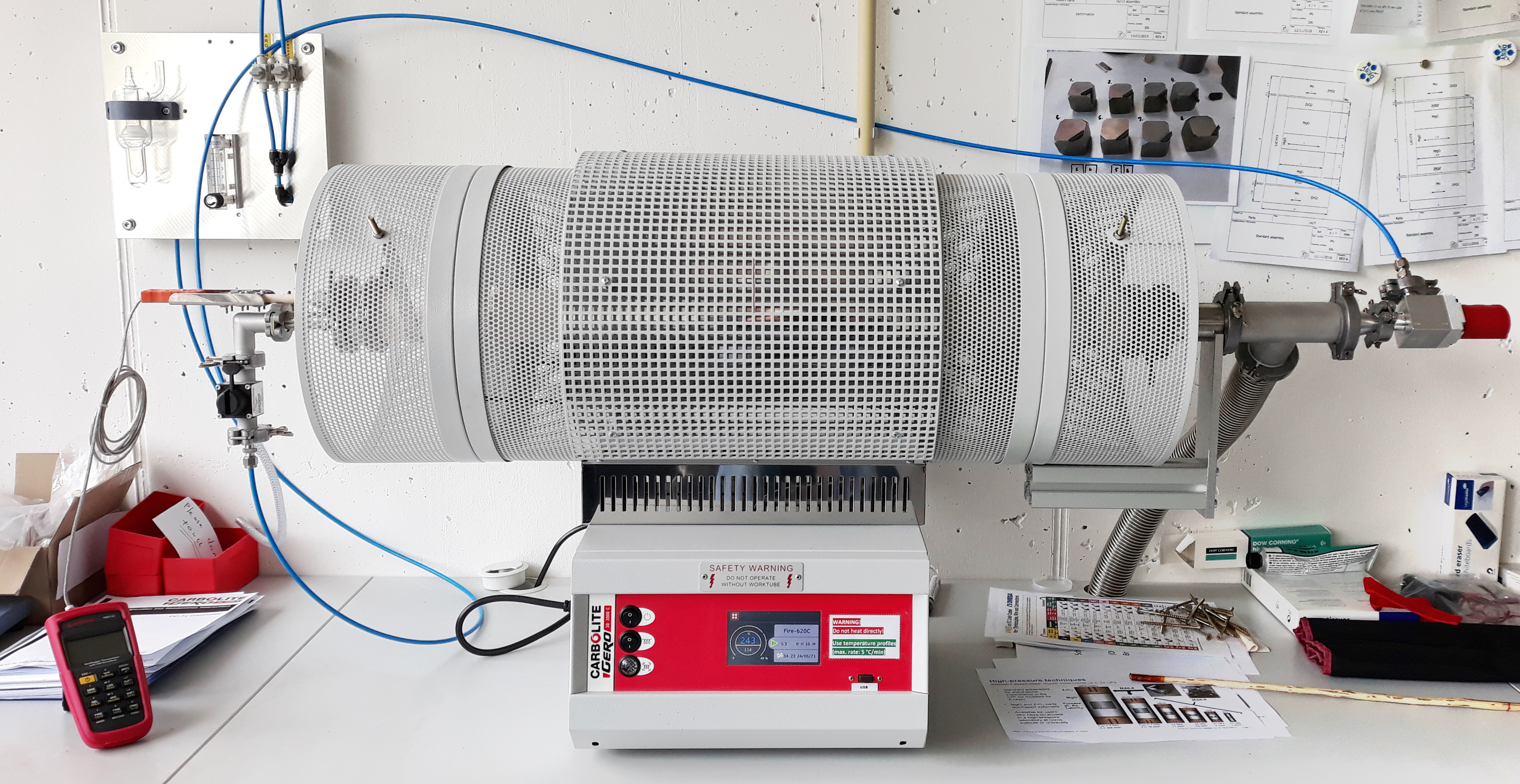

A vacuum furnace is available for users & inhouse scientists at the P61B beamline. The model is: Carbolite Gero STF15/180 without water-cooling. There are a few rules to follow when requesting access to this instrument.

Please contact the beamline manager (Dr. Robert Farla) at least 1 week in advance before planned use. Be thorough with your request to use the furnace.

Rules/limitations

- Max. temperature: 1400 °C for up to 1 hour. Lower temperatures: no time restriction, per se.

- Max. heating/cooling rate: 6 °C/min (to protect the alumina tubing)

- Max. temperature with vacuum (using turbopump): 1300 °C. The lowest vacuum pressure is about 5 x 10^-5 mbar

- Flushing or sintering under N2 or Ar gas atmosphere is possible

- Fused quartz boats up to 1000 °C, alumina boats up to max. temperature. Please consider bringing your own boats/crucibles; recommended length up to 50 mm

- How many days do you need? Propose a heating schedule to the beamline staff. All heating runs are pre-programmed as profiles, no manual heating allowed!

Keep in mind that access is primarily for beamline users and staff at P61B. Therefore, access may be offered on different dates than initially requested. You must come prepared. Bring all your cold-pressed sample powders (and boats).

For safety and security reasons, completely independent use of the vacuum furnace is not permitted.

Vacuum furnace specifications

STF 15/180: inner tube diameter 50 mm, and heated length (hot zone) 180 mm. Tube furnace: 220-240 V SR single phase 12A + N single zone. Dimensions (W x H x D): 625 x 600 x 375. CC-T1 touch screen storing 10 unique program profiles / 24 segments per profile. Thermocouple: Type-R inside the hot zone.

Requirements

*You MUST have done the online safety training for the following modules before you get access:

- BASIC

- PETRA III