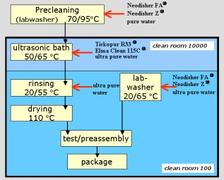

All components to be made particle free are usually precleaned using standard UHV cleaning procedures for degreasing e.g. high pressure cleaning systems or labwashers using standard detergents.

The following procedure is applied to stainless steel and copper components when the application of these parts does not care for surface oxidation.

The cleaning process starts with a fine degreasing of the components in the US bath using ultra pure water with either 1 % Tickopur R33 at 50

After manual ultra pure water rinsing using a hand spray above the US bath the component is transferred to the rinsing bath. Using the nitrogen buffer and minimizing the filling time of the bath, the rinsing in ultra pure water at a temperature of 50

The following drying process lasts 1.5 h at 110

Alternatively for small parts a labwasher is used. There are special washing programs for the different materials. As detergents neodisher® FA and neodisher® Z are used. Drying in the labwasher is also possible. Testing of these parts is done as previously described.

Finally the components are vented with dry nitrogen from a dewar, the flanges are closed off using plastic flanges (PTFE), and wrapped and sealed in two layers of antistatic plastic foil for storage and transport to the final assembly place.

Conclusion

A new cleaning facility for particle free UHV cleaning of accelerator and beamline components is under operation at DESY. The set up gives access to all needed cleaning procedures. First cleaning results for stainless steel components show satisfying results. The cleaning of oxide layer critical components needs further investigation as well as the criteria for a standard rinsing procedure.