US bath 1

Both requirements are important for accelerators using superconducting accelerating structures of high gradients as well as for optical components like mirrors used for the transport of intense photon beams in synchrotron radiation (SR) beamlines.

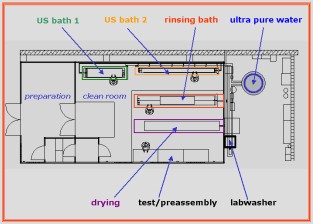

The goal of this facility is to combine standard cleaning techniques with latest clean room technology in a manageable way. Thus the new cleaning facility is installed in a clean room which fulfils class 10.000 and in its central part class 100 specifications*. The cleaning process following the standard UHV cleaning steps consists of a fine degreasing of the components in an ultrasonic bath. For rinsing ultra pure water[1] is used. Finally the components are dried using up to 110º C hot filtered air (according to clean room class 100 requirements). Comparable cleaning results for small components are achieved using a dishwasher, which is loaded from outside the clean room. Vacuum chambers of up to 4.8 m length can be treated.

A small preassembly area equipped with an oil free pumping station for leak detection and residual gas analysis completes the facility.

* cleanroom classification according US Fed. Standard 209E

[1] specifications according to semi conductor industry

Floor plan of the cleaning facility