Nearly all of the undulators for PETRA III, its extension, and for FLASH are planar devices with an antisymmetric hybrid structure made from NdFeB-magnets and Vanadium Permendur poles. For PETRA III the width of magnets and poles is 75 mm and 55 mm, respectively, in order to provide a “good field” region of ±25 mm which is required for high injection efficiency. The end-poles are designed in a 1:¾:¼ configuration which has been optimized for minimum gap dependence of residual kick errors in an iterative process using Radia.

A characteristic feature of linear accelerators is the round electron beam profile which is much narrower compared to storage rings. For stable operation the required “good field” region is only ±2 mm wide, therefore the width of poles and magnets for the FLASH 2 IDs could be reduced to 50 mm and 30 mm, respectively. This resulted in reduced magnetic load on the mechanics and less girder bending.

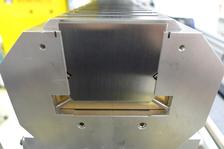

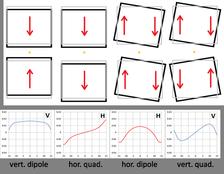

The mechanical design of the magnetic structure is an advancement of the well proven concept used for the FLASH undulators at DESY. 90 cm long support segments for magnets and poles are clamped onto the girders. As previously, local tuning of the magnetic fields is done by virtual shimming in order to minimize the phase error and to optimize the trajectory straightness. Each pole can be adjusted in height by ±100 μm and tilt by ±1 mrad to allow for tuning of vertical and horizontal dipole and quadrupole contributions.

A potentially remaining gap dependence in the 1st field integral after tuning and optimization can finally be measured and compensated for by dedicated corrector coils driven by the undulator control system. To allow for the correction of magnetic multipole errors, there is a compact retainer for “magic finger” correctors attached to each end of the magnet structure.