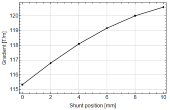

High gradient quadrupole magnets for fourth generation light sources should provide a 120T/m maximum gradient with gradient homogeneity of 5x10-4 and a static gradient tuning range of 5% by means of iron shunts. Such high magnet gradients push the existing resistive magnet technology to the limit as high performance and expensive material such as cobalt-iron alloys are required for the pole of the resistive magnet to reach high saturation level and achieve the specified gradient. Therefore, a permanent magnet-based quadrupole (PMQ) prototype is being developed in parallel to purely resistive high gradient magnets for PETRA IV. If successful, it would offer an alternative to conventional magnets which consume a lot of electricity and require a dedicated cooling infrastructure. A design based on permanent magnet (PM) technology would also have a more compact magnetic structure compared to a resistive magnet. Although a series production of PMQs is not foreseen for the PETRA IV lattice, this prototype that is under development in our group, will provide valuable results on the feasibility and future potential of permanent magnets in fourth generation storage rings.

The magnet design parameters of a PETRA IV high gradient quadrupole are given in Table 1.

|

Parameters |

Value |

Units |

|---|---|---|

|

Max Gradient |

120 |

T/m |

|

Nominal Gradient |

115 |

T/m |

|

Gradient tuning |

±5% |

|

|

Mechanic Length |

169 |

mm |

|

Bore radius |

11 |

mm |

|

Pole to pole gap |

8.8 |

mm |

|

Good field region |

6.5 |

mm |

|

Gradient homogeneity |

≤5×10^(-4) |

|

|

√(∑(b_n)^2 ) |

≤5×10^(-4) |

Contact: S.Yamin, M. Tischer