The mission of our sustainable materials group FS-SMA is to develop functionalised polymeric materials on bio-basis. Our research is embedded in the larger framework of sustainability. This comprises renewable materials themselves, enabling greener processes, energy harvesting, applying the principles of green chemistry as well as machine learning. Our focus hereby is to contribute to a circular bioeconomy! Current examples include novel hybrid materials for optoelectronic applications based on advanced bio-derived core-shell colloids, flexible solar cells and thermoelectrics. It extends to advanced biosensors based on (bio)polymer-inorganic colloid hybrid materials and lithographic applications.

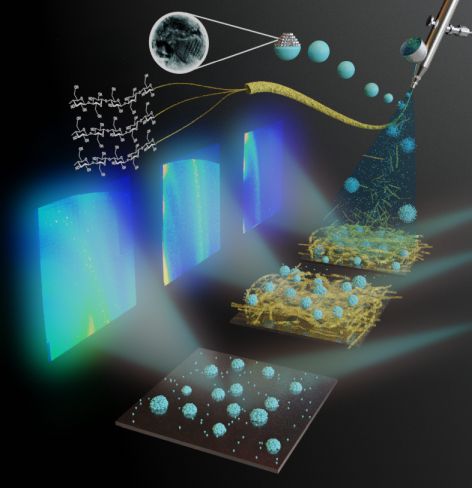

Self-assembly plays a crucial role in nanostructuring. Therefore, we are focusing on X-ray and neutron scattering at large scale facilities to establish the nanostructure-function relationship of these hybrid materials in real-time by so-called in-situ and operando experiments. The range of deposition methods for such thin films ranges from spray coating of liquid solutions to vacuum deposition on various metallic and organic films.

This image shows the spray deposition of a silver colloid - cellulose hybrid material for optoelectronic applications

Flexible electronics and photovoltaics uniquely combine organic templates and functionalized layers at the nanoscale to form hierarchical material structures. FS-SMA’s research is dedicated to sustainable, self-assembled and hybrid nanoparticle-biopolymer film for energy applications and potential light-weight construction. We develop and investigate advanced spray deposition as a fast, large-area and roll-to-roll compatible process technology for nano- and thin-film technology, especially for cellulose-based nanoparticle and biofilms. We functionalize cellulose-based nanoparticle-biopolymer films for application as biosensors and energy harvesting/storage materials.

Our vision is to use new material classes based on renewable, functionalized raw materials for flexible electronics. Using resource-efficient, environmentally friendly, scalable process methods, including 3D printing, we want to apply "green technologies" to tailor the complex, hierarchical material structures. We elucidate the fundamental steps of hierarchical material structure formation in real-time studies and correlate the forming nanostructure with its optical and electronic properties. Ideally, We am using the ultramodern characterization possibilities available at DESY and large-scale facilities world-wide. The complexity of the forming hierarchical materials requires new approaches to measurement and theoretical understanding to optimize the optical properties, at the nanoparticle level. Using this fundamental understanding, the nanostructure can be optimized for its respective function in a resource-efficient manner

Thus, our three research pillars are:

- Functional, colloidal and multiscale materials by layer-by-layer coating

- Renewable, sustainable materials for flexible electronics

- Complex, hybrid, locally anisotropic materials