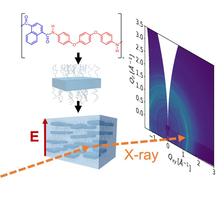

Hierarchical structure of semicrystalline polymers: (left) Schematic diagram of the hierarchical structure of semicrystalline polymers from polymer chains to lamellae to polymer films. Sketch of the X-ray scattering of polymer films with (right) 2D XRD scattering patterns of semicrystalline PEENA films (vertical direction is aligned with the film normal). (Credit: C. Shen, DESY (partly from original publication))

Capacitive energy storage materials possess the advantages of high energy density and speedy charge-discharging capability. In particular, polymer-based dielectric materials for high temperature operation condition are increasingly demanded for numerous emerging applications such as electric vehicles or aerospace power conditioning. So far, a common way to improve the energy density is to incorporate wide bandgap inorganic materials or constructing complex and sophisticated copolymers. To overcome such obstacles, a team from DESY and Jilin University in Changchun (China) leveraged the intrinsic formation of nanocrystallites in semicrystalline polymers to develop a single component homopolymer-based dielectric material that can operate efficiently at high temperatures of about 200°C and high electric fields of 500 MV/m. The results were published in Angewandte Chemie, International Edition.

“The intrinsically formed polymer crystallites are usually lamellae-like with a thickness of tens of nanometers. Can these crystallites achieve the same role as the nano-fillers in those inorganic-organic composite dielectric materials? It will consist of single components which simplifies material processing and makes it easily scalable.” says Wenhan Xu, the Helmholtz-OCPC postdoctoral fellow at DESY and Jilin University. Through rational molecular structure design, he produced a semicrystalline polymer film by using poly(diarylene ether naphthylamide) (PEENA). Its high-temperature capacitive performance outperforms all commercially available dielectric polymers (e.g. polyetherimide (PEI)) measured at the reference condition of 10 Hz and 200°C.

This excellence performance is attributed by its semi-crystalline nature. Throughout temperature range the semi-crystalline PEENA shows a better performance than the amorphous PEENA, and both are better than PEI, and the supremacy becomes more pronounced at higher temperature. Specifically, at 200°C under a high electric field of 500 MV/m, the discharge energy density of the semi-crystalline polymer reaches 4.52J/cm3 which is 160% of the amorphous polymer and 350% of PEI. Highly notable is also the disparity in charge-discharge efficiency η which typically decreases at higher electric field. The semi-crystalline PEENA maintains 95.7% of efficiency at high electric field (350 MV/m), whereas both amorphous PEENA and the commercial material PEI drop below 70%. The X-ray wide-angle diffraction data show that its excellent performance is made possible by its self-assembled nanolamellar crystallites. They are anisotropically oriented in parallel to the film surface which is typically perpendicular to the direction of the applied electric field. This result has significant implications for the development of polymer materials which are used under extreme conditions. All GIWAXS measurements were performed at the high-resolution diffraction beamline P08 at PETRA III.

This study demonstrates the excellent performance of these scalable dielectric polymers which could pave the way to urgently needed high-temperature energy storage. Insights were gained into the relationship between the hierarchical structure of polymer chains and the capacitive energy storage performance. It also points to a new direction for the development of high-performance polymer dielectrics, namely by optimising the intrinsic structural properties of semi-crystalline polymers.

Original publication:

Wenhan Xu, et. al., “Anisotropic Semicrystalline Homopolymer Dielectrics for High-temperature Capacitive Energy Storage”, Angewandte Chemie Int. Ed. (2024), DOI: 10.1002/anie.202319766